Femtosecond Laser Micro/Nano-Processing Via Multiple Pulses Incubation

A systematic review is conducted on the influence of laser repetition rate spanning from kHz to GHz.

CHENGDU, SICHUAN, CHINA, October 9, 2025 /EINPresswire.com/ -- Micro/nano-fabrication provides a unique platform to explore new applications in the fields of materials science, semiconductors, sensing and biomedicine. As a flexible and efficient non-contact processing technology, femtosecond laser has been widely applied in various micro/nano-precision engineering, leveraging its ultra-short pulse duration and ultra-high peak power density. Femtosecond laser manufacturing is mostly conducted under multiple pulses irradiation. The incubation effect based on multiple pulses irradiation provides new theoretical and technical support for precision manufacturing. With breakthroughs in laser technology, the pulse repetition rate of femtosecond lasers has increased from the early kHz to the current GHz, spanning six orders of magnitude. This leap has driven exponential improvements in processing efficiency (from thousands to billions of pulses per second). Meanwhile, due to the extremely short pulse interval of high-repetition-rate femtosecond lasers, the multiple pulses incubation involves more complex light-matter interactions, which presents both challenges and opportunities. The diversification of incubation mechanisms under different pulse repetition rates not only expands the materials applicability of femtosecond laser processing but also promotes full scenario technological innovation from surface micro/nano-structuring to three-dimensional functional device fabrication, providing a new path to realize various extreme manufacturing.The research group of Prof. Minghui Hong from Xiamen University and Prof. Lingfei Ji from Beijing University of Technology are invited to publish a review entitled "Femtosecond Laser Micro/Nano-Processing Via Multiple Pulses Incubation" in Opto-Electronic Technology, Vol. 2, 2025. The review systematically summarizes the key progress and future development trends of femtosecond laser precision engineering based on multiple pulses incubation, with a special focus on nanomanufacturing via high-repetition-rate femtosecond lasers.

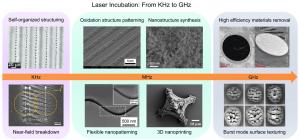

The physical mechanisms of three incubation modes: defects accumulation at kHz, heat accumulation at MHz, and plasma interaction at GHz are comprehensively analyzed. By integrating practical applications, the latest progress in femtosecond laser precision engineering based on multiple pulses incubation is emphatically introduced, as depicted in Fig. 1.

At a repetition rate of kHz, the incubation effect manifests as a reduction in the ablation threshold due to the accumulation of surface defects inside materials. By optimizing parameters, such as laser fluence, scanning path, and polarization, to regulate the defects incubation process, the formation of self-organized structures and near-field breakdown nanostructures are achieved. When the pulse repetition rate reaches MHz, the pulse time interval and the materials thermal relaxation time reach a dynamic equilibrium, resulting in the heat accumulation between adjacent pulses. Through the precise control of this thermal incubation, various processes can be realized, such as oxidation structure patterning, nanostructure synthesis, flexible nanopatterning, and 3D patterning. At a GHz repetition rate, the subsequent pulse can directly interact with the plasma generated by the previous pulse. This interaction significantly enhances energy coupling, leading to the emergence of high efficiency materials removal and burst mode surface texturing. These processing strategies based on the multiple pulses incubation provide unique insights for the femtosecond laser precision engineering.

This research group systematically explores the physical mechanisms of the femtosecond laser multiple pulses incubation effect from kHz to GHz, and summarizes the latest research progress in the field of micro/nano-processing. In the future, breakthroughs in femtosecond laser incubation processing will focus on the four following directions: first, developing a multimodal in-situ monitoring system for the interaction between high-repetition-rate femtosecond laser and materials; second, further suppressing the heat-affected zone through pulse energy and spatial beam shaping; third, expanding the nano-fabrication capability of GHz femtosecond laser; fourth, improving production efficiency through parallel processing to promote technology commercialization.

About the Authors:

Prof. Hong Minghui is the Fellow of Singapore Academy of Engineering. He joined Xiamen University as a full-time professor in August 2022 and was appointed as Tan Kah Kee Chair Professor. He is the Dean of Pen-Tung Sah Institute of Micro-Nano Science and Technology and the Chairman of the Faculty of Engineering of Xiamen University. Prof. Hong is a Fellow of Optical Society of America (OPTICA), International Society for Optics and Photonics (SPIE), Institute of Engineers, Singapore (IES), and Chinese Society for Optical Engineering (CSOE). He is also a Founding Fellow and Vice President of International Academy of Photonics and Laser Engineering (IAPLE). His main research direction focuses on laser micro/nano-processing and detection technologies, conducting internationally leading research in areas such as laser micro/nano-manufacturing, laser cleaning, and optical inspection.

Read the full article here: www.oejournal.org/oet/article/doi/10.29026/oet.2025.250003

Andrew Smith

Charlesworth

+44 7753 374162

marketing@charlesworth-group.com

Visit us on social media:

LinkedIn

YouTube

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.